We take pride in the services we are able to offer to our clients. Our extensive range of machinery (both principal and support equipment) means that most stages of production occur in-house and our quality assurance procedures ensure that a quality product is produced everytime.

Cast irons that perform under conditions of temperature and friction in accordance with individual customers requirements. Engineering irons conform to Australian Standard AS1830 and special attention is paid to machining characteristics of modern high speed finishing processes.

Ductile iron is produced to satisfy individual customer needs Australian Standard AS1831.

Austempered Ductile iron, which is produced by subjecting ductile iron castings to a two way stage heat treatment process similar in duration to that used for heat treating steel.

Ongoing investment in advanced techniques of melting and core making equipment, combined with the constant research and modern technology has enabled Ajax Foundry to meet demands of the Australian and, increasingly, the export market.

Our diverse range of principal equipment makes Ajax Foundry a key asset in casting manufacture. Our range of principle equipment includes:

2 x DISA Match 130 Moulding Machine

Three Electric Induction Furnaces (2 tonne)

Power Packs (1,500 kW)

DISA Sand Mixer with automated green sand controlling unit www.disa.com

Core Manufacturing Machines

Three Leampe Core Shooting Machines www.laempe.com

Sinto Automatic Pouring Systems www.sinto.com

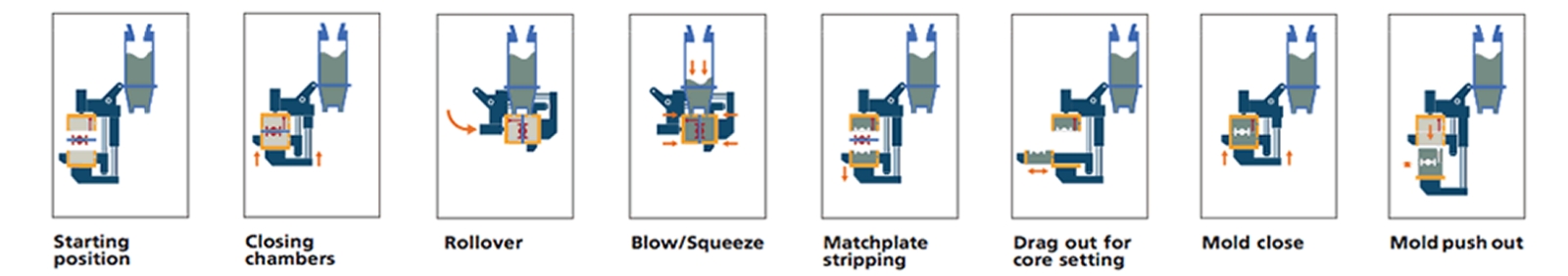

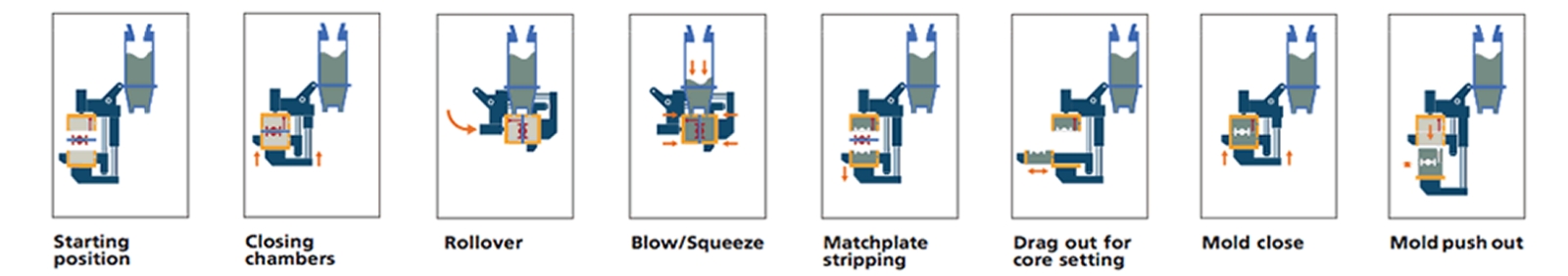

In 2008, Ajax Foundry introduced a new addition to their principal equipment, the DISA Match. In 2011, Ajax Foundry introduced a second DISA Match. The DISA MATCH is a highly reliable and efficient machine, producing high-quality castings. By combining vertical and flaskless horizontal molding technologies, the DISA MATCH offers high precision, speed and quality. www.disagroup.com

Cast irons that perform under conditions of temperature and friction in accordance with individual customers requirements. Engineering irons conform to Australian Standard AS1830 and special attention is paid to machining characteristics of modern high speed finishing processes.

Ductile iron is produced to satisfy individual customer needs Australian Standard AS1831.

Austempered Ductile iron, which is produced by subjecting ductile iron castings to a two way stage heat treatment process similar in duration to that used for heat treating steel.

Ongoing investment in advanced techniques of melting and core making equipment, combined with the constant research and modern technology has enabled Ajax Foundry to meet demands of the Australian and, increasingly, the export market.

Our diverse range of principal equipment makes Ajax Foundry a key asset in casting manufacture. Our range of principle equipment includes:

2 x DISA Match 130 Moulding Machine

Three Electric Induction Furnaces (2 tonne)

Power Packs (1,500 kW)

DISA Sand Mixer with automated green sand controlling unit www.disa.com

Core Manufacturing Machines

Three Leampe Core Shooting Machines www.laempe.com

Sinto Automatic Pouring Systems www.sinto.com

In 2008, Ajax Foundry introduced a new addition to their principal equipment, the DISA Match. In 2011, Ajax Foundry introduced a second DISA Match. The DISA MATCH is a highly reliable and efficient machine, producing high-quality castings. By combining vertical and flaskless horizontal molding technologies, the DISA MATCH offers high precision, speed and quality. www.disagroup.com

Whether you need precision castings, technical advice, or a custom solution — our team is ready to help.